Project News

Updated July 2023

Full-scale rockweed (Ascophyllum nodosum) harvesting in Nova Scotia began in 1959. Individual harvesters working from open boats up to 6 meters long (Figure 1A) on a rising or falling tide used long 3-meter poles with a cutting blade attached to a rake head with wide-spaced tines (Figure 1B). In the Annapolis Basin, due to the extreme low tides, harvesters could walk onto the intertidal zone and cut rockweed with specialized knives.

Figure 1A. Rockweed harvester with cutter rake.

Figure 1B. Cutter rake head with rake tines, cutter blades, and guides.

This manual method has been used since then with some changes in design but not principle. However, by 1969 mechanical methods were introduced to supplement the manual methods of cutting and gathering. Machine harvesting provided enhanced control of the flow of raw material to the processing plant. The first successful mechanical technology used by Scotia Marine Products of Woods Harbour was based on a reciprocating cutter and conveyer system mounted on a paddle wheel propelled vessel, the Aquamarine harvester (Figure 2).

Figure 2. The Aquamarine harvester, operated by Scotia Marine Products Ltd. in southwestern Nova Scotia.

This machine operated in the Lobster Bay area harvesting 60% to 80% of the landings until 1985. Manual harvesting methods were concentrated in the Wedgeport, St. Mary’s Bay, and Annapolis Basin regions.

A new harvesting machine developed in Norway was brought to the region by ProNova Ltd. in 1986 when it purchased Scotia Marine Products Ltd. This machine was based on a combined cutter head and suction pump mounted on a vessel that is propelled by water jets (Figure 3). This machine harvested up to 80% of the landings overall and operated until 1993. Economics and changes in leasing allocations led to ProNova Ltd. leaving Nova Scotia and taking the technology with it.

Figure 3. The Norwegian suction cutter operated by ProNova Ltd. in southwestern Nova Scotia.

Tidal Organics has reintroduced a method of mechanical harvesting of rockweed to Nova Scotia after 23 years of its absence. This technology left Nova Scotia due to a business decision of Protan AS, a Norwegian company, which purchased Scotia Marine Products Ltd. from a USA company Kelco Inc. The Norwegian company replaced the Aquamarine reciprocating cutter harvester with its suction cutter brought from Norway. This company took its technology back to Norway when it determined it could not be assured of sufficient resource to be allocated for expansion. The remaining leaseholders chose to buy rockweed from manual harvesters until the lack of sufficient sources of labour led both Tidal Organics Inc. and Acadian Seaplants Ltd. to consider the reintroduction of mechanical harvesting.

Mechanical methods continue to be used to harvest rockweed in the USA, Iceland, Scotland, and Norway to the present day. Nova Scotian harvests became 100% manual until 2017 when Tidal Organics began experimental studies of a suction cutter harvester chartered from Maine. The reason for this initiative was twofold. Firstly, to improve the management & utilization of the resource. Secondly, to supplement & complement the manual harvest. An aging harvesting force and competitive fisheries were leading to a shortfall in the annual harvest. More controlled harvesting geographically & seasonally would improve resource management in the long term.

This machine used a hydraulically driven cutter blade ahead of a pump unit to cut and provide suction. The cutter was oriented parallel to the bottom and its height controlled by the operator. The machine is driven by hydraulically powered thrusters when harvesting and by an outboard motor when travelling (Figure 4). The rockweed is severed and pumped into a bag on the side of the vessel. Bags are temporarily moored near the harvest site until they are towed to a landing site (Figure 5).

Figure 4. Tidal Organics’ mechanical harvester “Tidal Bay” cutter head submerged.

Figure 5. The Tidal Bay operating near a cluster of moored bags pumping into side-mounted bags.

The controlled experimental harvests were conducted with the review & approval of the Nova Scotia Department of Fisheries and Aquaculture (NSDFA). These studies were conducted at five sites to determine the harvest efficiency, impact on the resource, associated macrofauna, and habitat structure. These sites were monitored for two years to evaluate regrowth of the resource and impacts. The results were promising in all aspects when exploitation rates were kept within the 20% limit. Within this limit, the impact on the habitat and associated macroinvertebrates was short term and the machine was able to sustain an economic harvest rate.

Based on a review of these results, Tidal Organics proposed to build its own machine modelled after the Maine machine. It then proposed a pilot-scale harvest to NSDFA for 250 short tons of harvest to allow for a true commercial trial in 2019. This tonnage was to be taken in quotas calculated from the resource assessments of 15 individual sectors in Lobster Bay and southwestern Nova Scotia, both areas containing leases of Tidal Organics. The primary difference between the experimental harvest and the pilot harvest was that the experimental harvester operator was able to optimize the harvesting rate depending on the tide, weather, and resource abundance within the quota per sector. The pilot harvest will test the economics of more realistic conditions.

Due to time delays during construction of the vessel, the pilot harvest did not commence until late in the 2019 season and only one sector was partially harvested. The limited commercial trial was promising with observations including the high resolution of harvest track, no whole plant mortality, and a cutting height well above the regulation limit.

In 2020, the machine worked in the Pubnico, Port Medway, and Port Mouton areas to harvest a total of 68.6 short tons. The post-harvest surveys of the targeted beds confirmed the initial information on the positive features of this harvester regarding harvesting characteristics and impact. The ability to have a GPS track for the harvester allowed Tidal to plot very closely the daily location of the harvest. This information provided unique data on the exploitation rate within the track of the harvester. A great deal of information was gathered on the operation of the harvesting machine and the logistics of material handling.

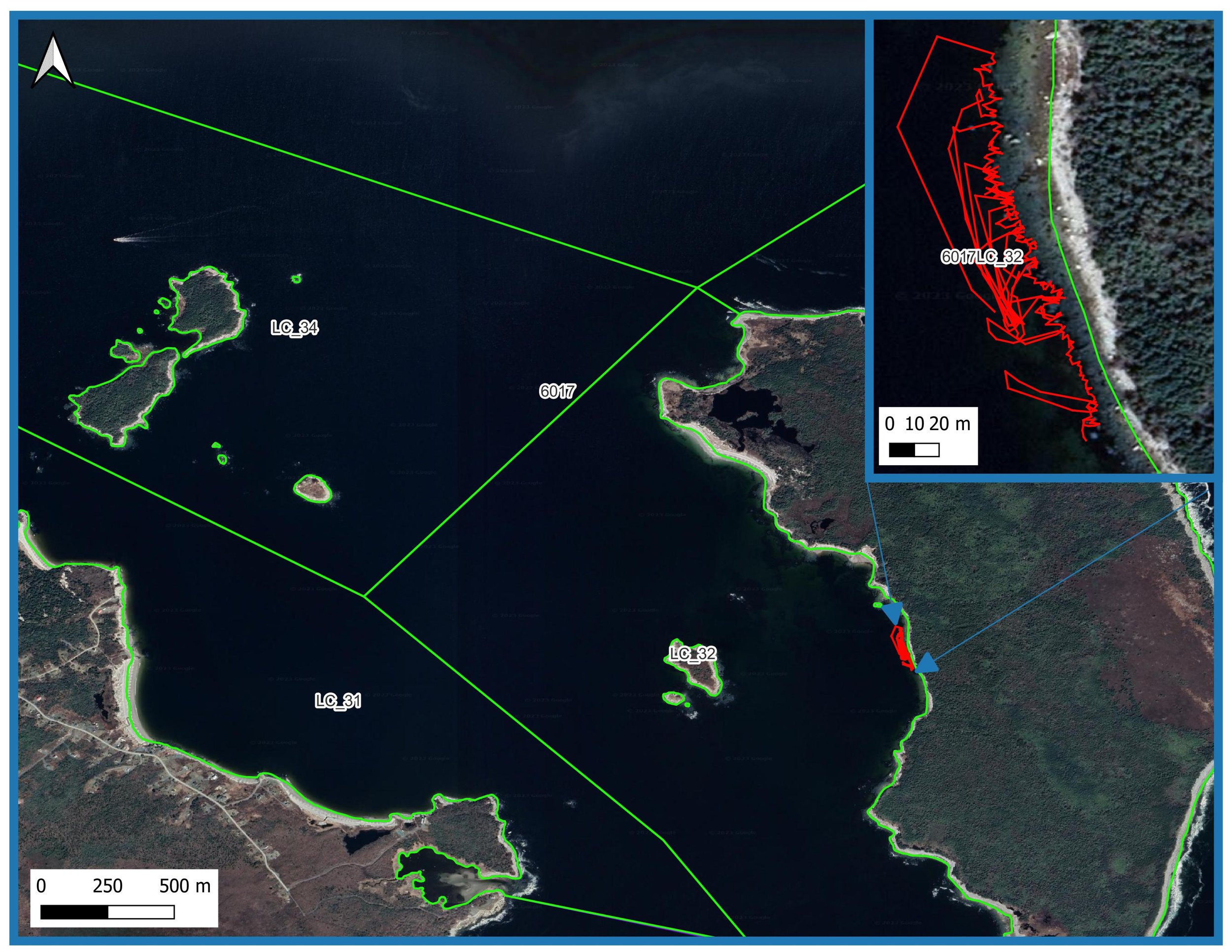

A Raymarine Elements chartplotter proved the opportunity to record the position of the harvester every 30 seconds to a resolution of 3-4 meters (Figure 6). When the machine reached the targeted beds for harvest each day, the chartplotter was turned on and the track was recorded until turned off at the end of the harvest. The number of bags filled each day was recorded and the weight of the combined bags for each day & sector were weighed at the plant. Lines were drawn on a map based on the maximum limits of the daily harvester tracks.

Figure 6. Tracking of the mechanical harvester’s trail (red) in sector LC-32 inserts tracks on the targeted rockweed bed

It was possible to calculate the area of days harvested using QGIS, a GIS mapping software. A great deal of information was gathered from the relationship between tracking the harvester and the yield per hour of the harvesting activity or catch per unit effort. This rate can be impacted by many factors such as the height of the plants, weight & density of plants per unit area, tide & weather conditions, the relief & slope of the bottom, and lastly the skill & determination of the machine operator.

A first for this industry was the ability to determine the exploitation rate of the machine with an area resolution vastly greater than the regulated sector units of management. Sectors range between 0.16 hectares to 17.65 hectares. Polygons of rockweed beds within the sectors range from 0.001 hectares to 0.231 hectares. This opens a new level of management for the company to both utilize the resource efficiently and increase the level of precautionary harvesting as it relates to ecosystem management and preservation of the intertidal habitat.

Following a preliminary report to the provincial government, reassessment of targeted sectors, and acceptance of a management plan, Tidal Organics continued the pilot scale harvest in 2021 landing 110 short tons. A final pilot scale harvest report was provided to the NS Department of Fisheries and Aquaculture in December 2021. Each year of the pilot harvest, a pre, post, and one-year-post monitoring report was required. The monitoring reports focused on any changes in biomass, clump length, holdfast retention, and presence or absence of major fauna. Based on the positive results in this report, a continued pilot harvest was developed for 2022 and approved in June 2022.

Tidal Organics submitted a proposal to conduct a controlled harvest within 7 sectors in its southwestern & south shore leases in 2022. Pre-harvest surveys were used to set sector quotas based on a 15% exploitation rate. Selected sectors were restricted to mechanical harvesting only to prevent overlap in assessing the impact. The monitoring program included holdfast retention, daily landings, and daily tracking of the harvester. The post-harvest monitoring program examined clump length & biomass.

A total of 215 short tons were landed in 2022 with an average exploitation rate of 6.8% in the harvested sectors. Following the submission of a comprehensive report detailing the 2022 harvest, NSDFA developed a draft mechanical harvesting policy, that is now in effect as of May 25, 2023.

Five years of research & monitoring program data has been consistent year to year on the most important factors that impact both sustainability & the preservation of the habitat and the ecosystem services it supplies to the coastal zone.

The Tidal Organics harvesting machine cuts the Ascophyllum clumps at an average of 50 to 60 cm above the substrate, well above the regulated 20 cm guideline. The machine is selective of the longest clumps and removes the biomass from the top of the clumps. One year after harvesting, the biomass has recovered to pre-harvest values. Holdfast retention equivalent to whole clump removal was far below the rates recorded in the industry to date. These have been the most important criteria since the development of the industry in 1959 and have been the regulations of both the provincial & federal government. They are the basic variables that affect both the sustainability of the harvest and the protection of ecosystem services of the habitat.

The management of Ascophyllum harvests is area based divided into the previously mentioned sectors that range from 0.16 hectares to 17.65 hectares. For the first time in this industry, the use of GPS tracking permits the control of exploitation rates at a very high geographic resolution well below the present regulated sector scale. It enables both the company and the management agency to have real-time information that can be used for day-to-day harvest planning & agency monitoring.

As a result of the accumulated knowledge over the past five years by Tidal Organics and the review of this data; NSDFA has permitted the use of mechanical harvesters by all leaseholders in 2023 as an accepted harvesting method. Pre-harvest assessments & management plans will be paired with landing reports & monitoring. Exploitation rates within sectors will be limited to 20%. Mechanical harvesters will be tracked daily and changes in harvesting methods will require notification of NSDFA.

The machine will only operate during daylight hours and will endeavour to avoid disturbance of other coastal activities. Daily operational plans will be provided to the department rockweed manager. Monthly summaries of landings & locations of the harvest within sectors will be provided to the NS Department of Fisheries and Aquaculture.

Tidal Organics is proud to have been leading the research & development program to reintroduce mechanical harvesting to the Nova Scotia seaweed industry. Our company has made constant improvements in all aspects of its operations over the past 25 years using scientifically sound information. The mechanical harvester economically deals with challenges of labour supply and most importantly international competition in the world seaweed marketplace.

The future of this method is not to displace harvesters but to supplement & complement traditional management. Harvesters optimize their harvest and some parts of the resource are underutilized. Where the resource is more diffusely spread or discontinuous, it is not economically harvestable by manual methods.

Our company is open to examination of its harvesting activities and welcomes questions on our management plans & procedures.

Environmentally, this is a step forward in ecosystem sustainability & accountability of the industry.

For additional inquiries, please use the form on the Contact Us page.